Fast Facts

Area - 280 hectares: 100 hectares irrigated for milking cows, 72 hectares dryland pastures often shared between milkers, dries and heifers and 108 hectares used exclusively for dry cows and heifers.

Herd (December 2019)

| Milkers | 285 |

| Dry cows | 38 |

| Springers | 24 |

| Heifers | 138 |

| Calves/Weaners | 64 |

| Bulls - Beef | 1 |

| Bulls - Dairy | 1 |

| Total | 551 |

Production - Average production is 35,000 – 45,000 litres/week or 2.2 to 2.5 million litres in 2019.

Pastures - Kikuyu-based oversown in early autumn with ryegrass, white clover and red clover with some chicory and plantain. Also forage crops such as sorghum, lucerne and maize for silage.

Irrigated area - 100 hectares total. The system has five travelling irrigators and three centre pivots.

Fertiliser - Starter fertiliser, selective use of nitrogen and poultry litter. Some paddocks are limed. Fertilised with N+P+K regularly.

Milking Parlour - 15 a side parallel stall gate system.

Milking time - 120 minutes (approximately).

Average Production/Cow lactation - 7,700 litres.

Seasonal Update 2020

The Tocal dairy has had a very strong year given the difficult seasonal conditions. High temperatures, low rainfall and long dry stretches made managing pasture difficult. The Paterson River once again came to the rescue. Tocal has a licence to irrigate from the unregulated tidal pool of the Paterson River. This allows consistent irrigation and 22 ha of maize for silage has been sown and another 15 ha of sorghum. The irrigation will keep up with this area and the hope is for summer storms to support this crop.

The major news for the dairy was the decision early in the year to move our supply arrangements to Norco Cooperative. Norco offered a significantly higher milk price and a supply bonus for a long-term five-year contract. After a thorough investigation and following Saputo transfer rules, the supply contract with Norco commenced in December with the first delivery of milk on the 20th.

The dairy farm has a milking herd averaging 280 - 300 mostly Holstein-Friesians with some Aussie Reds and cross-breeds. With dry cows, heifers (grown for replacement and sale) as well as calves the dairy herd is about 550 - 600 head at any time throughout the year. Cows are milked twice a day and the average production per cow is 24 litres per day. Total milk production for the year is approximately 2.2 million litres. The milking herd is mostly artificially bred with sexed semen being purchased from USA, Canada and Australia. Herd recording is undertaken once a month to monitor individual animal performance and assist in management decision making. The NLIS tag, in each animal’s ear, is scanned to assist in this process. Our herd records are maintained electronically using EasyDairy software.

Pastures are managed using the “Managing Pastures for Profit” system devised by the Dairy Pathways project. Additional concentrate feeding occurs during milking and on a feed pad as required. Depending on seasonal conditions about 500 tonnes of silage and hay is made from surplus pasture each year and is fed out to the cattle when needed.

The dairy is both Cattlecare and HACCP (Hazard Analysis and Critical Control Point) accredited. The finances of the Dairy business are monitored and reviewed as part of the Dairy Farm Monitor Project sponsored by NSW DPI and Dairy Australia.

For more images taken on the Tocal dairy go to our Tocal Farms Flickr album https://www.flickr.com/photos/tocalcollege/albums/72157664513318258

For videos about the Tocal farms go to our YouTube channel (NSW SPI Schools Program) https://www.youtube.com/playlist?list=PLCw_zxSFv4qdluVIhRWpM6R39KFqro5BA

Details

Size of the farm: 280 hectares: 100 hectares irrigated for milking cows, 72 hectares dryland pastures often shared between milkers, dries and heifers and 108 hectares used exclusively for dry cows and heifers.

Herd size

Numbers can fluctuate throughout the year but average number of milkers are given below:

- 2017-19 = 280

- 2016 = 200

- 2015 = 225

- 2014 = 225

- 2013 = 180

In 2019 herd reproductive performance continues to meet all industry targets for average Days in Milk (DIM) with 57% of the herd < 150 DIM with average DIM at 155days (industry target is 160-180 days), 80-day submission rate at 67% and 100 day in calf rate at 33%.

Herd composition

The great majority are Holstein (95%) with some Illawarra and Illawarra cross from a previous herd acquisition. In the past Tocal has run a Jersey bull with maiden heifers and approximately 5 Jersey x Holsteins remain in the herd.

Overview of milk production

Cattle graze pasture or receive supplementary feed on the feed pad. They are brought to the dairy twice daily for milking where their milk is extracted by milking machines under controlled vacuum. The milk is then pumped through a filter and plate heat exchange unit (plate cooler) into a vat (refrigeration unit). Milk is further cooled to <4o C and collected by a B-double milk tanker every second day (Skip-a-day pick up) for transport to Raleigh near Coffs Harbour for processing. Processing includes pasteurisation, homogenisation and packaging where it is then distributed from processor to supermarkets and retail outlets. Milk vendors are sometimes used during distribution which may (rarely) include home delivery.

Milk per cow/day

Fluctuates with season and ‘freshness’ of herd (i.e. average number of days since calving, also called average Days In Milk (DIM) or Days Open). Common range between 22-30 litres per cow per day and the average over the year is 25 litres per cow per day.

Some farms have three milkings per day and robotic dairies allow even more, this will often increase production of milk per cow per day.

A significant amount of energy is used by a cow grazing and consuming pasture in the Tocal property and farms (2021 update) 56 paddock. A grazing cows’ metabolisable energy (ME) use is around 24% of energy consumption compared with a confinement cow (a cow housed in a barn with feed brought in) only using about 10% on ME.

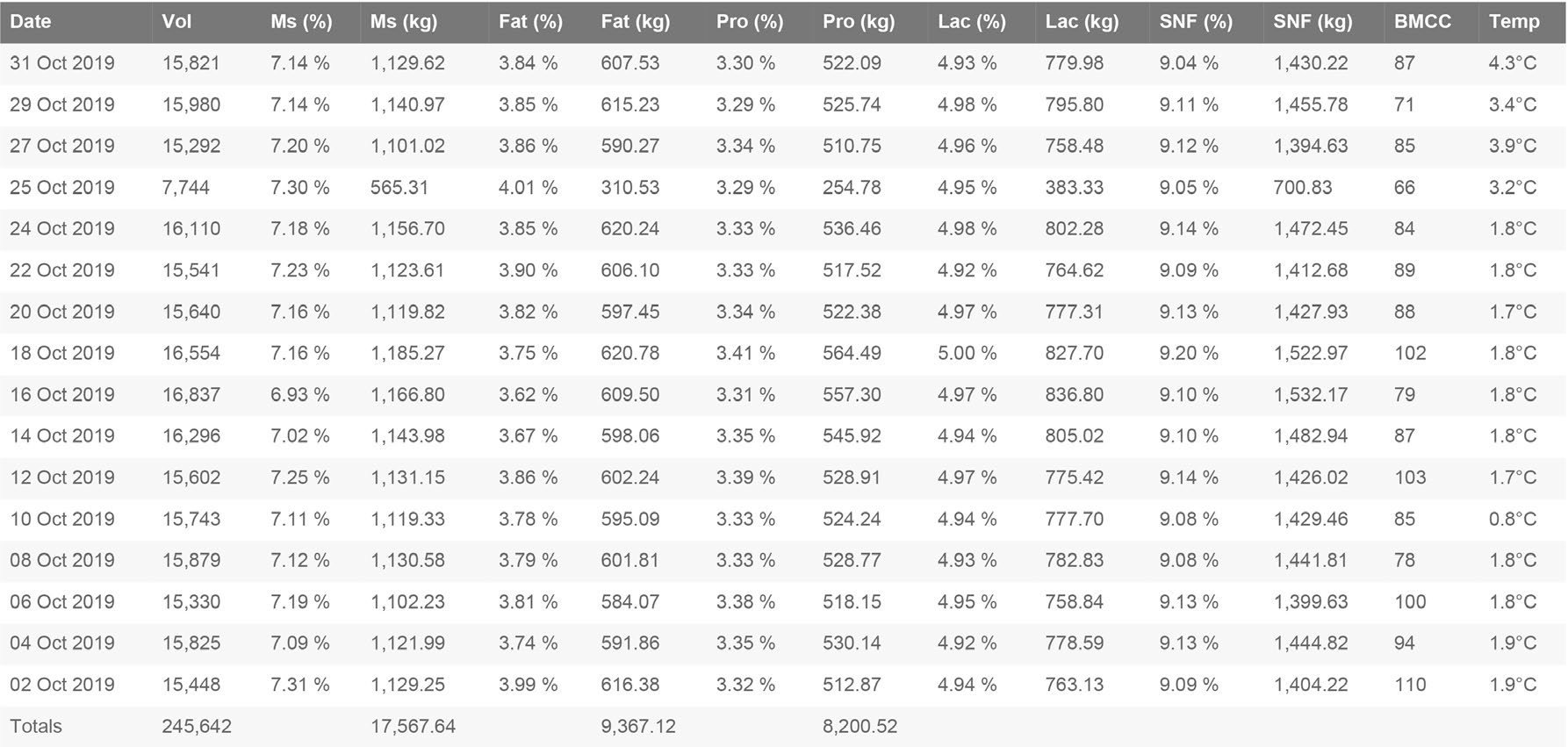

Quantity of milk collected each day

Fluctuates with season and ‘freshness’ of herd. Common range between 10,500 and 16,000 litres per pickup (note Tocal is usually on “Skip-a-day Pickup” so daily production is half the pick-up amount). In the autumn production will be approximately 10,500 litres per pickup rising to 16,837 litres in Spring 2019. The variation in production is due to seasonal conditions, cow numbers and cow condition.

Quality fluctuates also. Key measures of milk quality are Protein and Fat %, Somatic Cell Count (a measure of udder health, especially mastitis), Total Plate Count (a measure of bacterial contamination), Extraneous Matter (a measure of general milking hygiene) and Residue testing for contaminants such as chemicals or medicines. Demerit points can be awarded for milk that does not reach quality targets and this then affects the price received. Tocal produces good quality milk and normally achieves payment in the ‘premium’ milk quality band.

A sample milk production report is shown below.

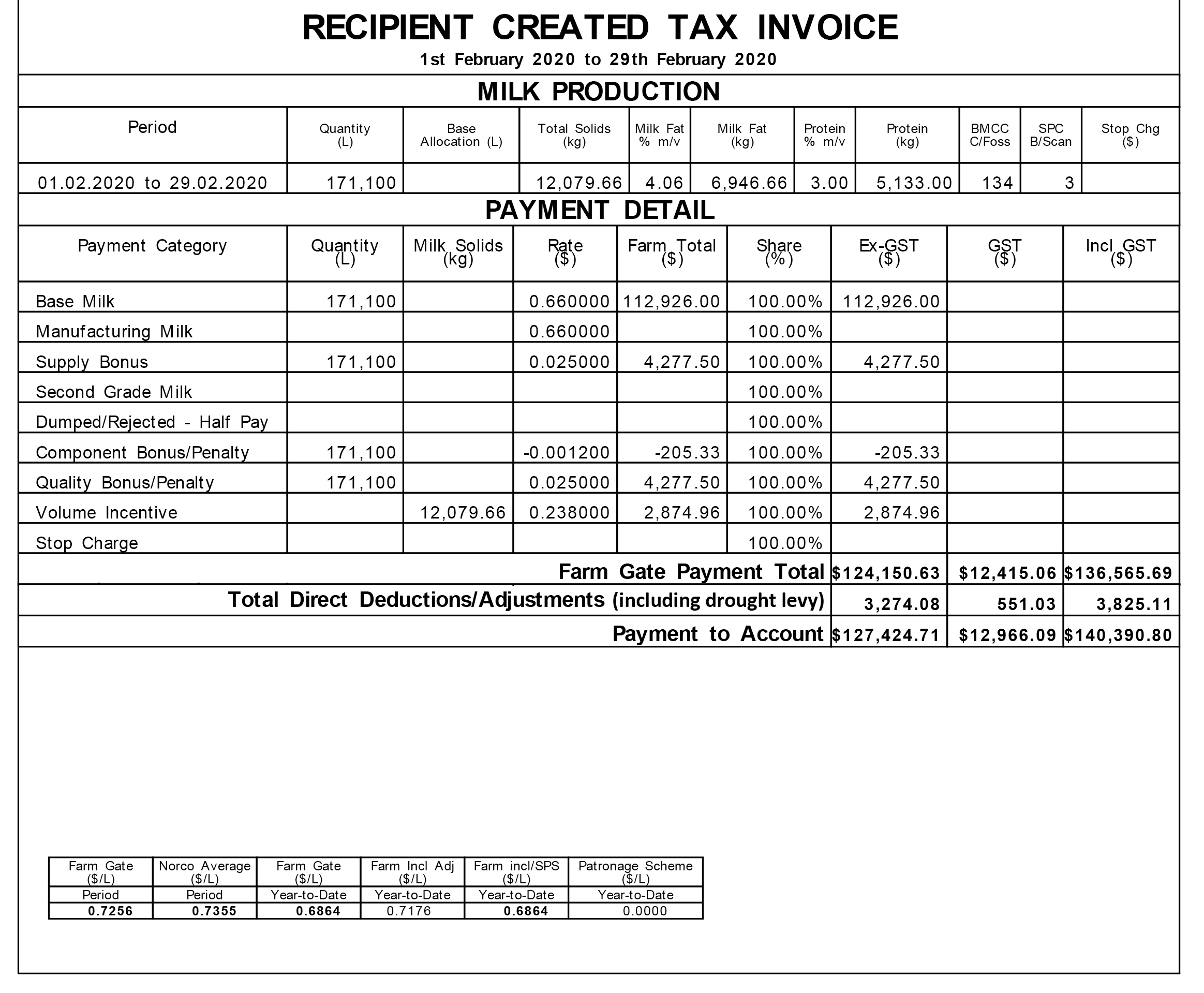

Farmgate price

Actual price is affected by quantity, quality and supply management factors. The farmgate price for Tocal for February 2020 was 72.56 cents per litre (65.45 cents per litre last year). This figure is calculated on a base rate of 66 cents per litre. Tocal achieves additional payment for factors including:

- milk fat over 3.95%,

- protein over 3.2%,

- somatic cell count under 200,000 cells per millilitre,

- volume incentive,

- drought levy, and

- fixed term contract signed with Norco.

| Production | 2017 | 2018 | 2019 |

| Total Litres | 1,884,613 | 2,308,952 | 2,447,215 |

| Total Milk Solids | 130,368 | 159,300 | 175,982 |

An excellent, in depth review of factors affecting the price for milk and milk products and also of inputs such as grain, fertiliser, water, etc is provided in the Dairy Situation and Outlook available at: https://www.dairyaustralia.com.au/industry-statistics/industry-reports/situation-and-outlook-report

Part of a sample milk statement is provided below.

Quota level and surplus average price

Regulation of the national and state dairy industries ceased in 2000. From this time onwards the NSW Dairy Industry dispensed with formal quotas.

Some excellent resources about markets and farm gate pricing are available on Dairy Australia’s website at: https://www.dairyaustralia.com.au/industry-statistics/industry-reports/situation-and-outlook-report

Cattle sales

The increased heifer numbers through the use of sexed semen in the AI program has also provided an opportunity to sell young heifers through to export placement with 40 heading for Indonesia in December and January.

Prices received for cull cattle sold direct to abattoirs over the past 12 months have been higher than past years. We have achieved $1800 per head for our top priced cattle.

Costs of supplementary feed

The Total cost of feeding the herd can be up to 60% of all costs. The feed costs are be broken into home grown feed and purchased feed. The total feed cost at Tocal in 2019-20 were $1.01m. These costs include fuel, oil and repairs to machinery, irrigation, silage and hay production/storage and all purchased grain and fodder. The total feed costs are for all milkers, dry cows, heifers and calves.

This cost fluctuates markedly depending upon season—either locally, regionally or internationally— as this affects supply and demand. It is also affected by international monetary factors such as exchange rate and world trade regulation (tariffs, import quotas, etc). Grain prices commonly fluctuate between $300-450 per tonne and are perhaps the most affected by drought conditions and international factors. Hay and other feed commodities that are less likely to be exported are less affected by international price fluctuations however seasonal shortages still create market volatility.

Dairy Australia provides a national commentary on Hay and Grain prices alerting farmers to likely price movements. Their regular on-line report can be found at: https://www.dairyaustralia.com.au/Pastures-and-Feeding/Supplements/Hay-and-grain-report/International-and-national-grain-report.aspx.

Freight costs can also be significant so the distance that feed can be sourced from the farm has an impact. Current feed barley prices are around $350 per tonne from the farm supplier plus around $50 per tonne cartage. During the drought this cost rose to Tocal property and farms (2021 update) 59 over $450 per tonne.

In a typical year Tocal Dairy may spend around 40% of total costs on grain and supplements. This cost is equivalent to approximately 18-21 cents per litre.

We have experienced one of the worst droughts in recent history over the summer of 2019/2020. Hay became impossible to source and we were running very low on stock drinking water in farm dams – some were completely dry. We started that season with considerable fodder conserved. This was used up by the start of December and we fortunate to be able to source extra wheat and canola silage from the NSW DPI site at Wagga Wagga.

Costs of pastures

Estimated cost to the business for fertiliser and pasture in 2019-20:

- Urea: $81,729

- DAP (starter fertilisers): $13,090

- Seed: $67,647

- Contractor services: $108,832

- Irrigation electricity: $35,000

This cost fluctuates markedly depending upon seasonal factors that affect pasture growth rate including need for irrigation plus the cost of inputs such as fertiliser, irrigation water, electricity and fuel. These are discussed in more detail in the online Dairy Situation and Outlook reference previously provided. Significant irrigation costs were incurred last spring and summer at Tocal due the need to irrigate throughout the drought.

Cost of artificial insemination (AI)

Sexed semen is approximately $40-50 per straw, Angus semen is $12 per straw.

Tocal’s expenditure on semen is $46,833 p.a. This equates to around 1.8 cents per litre.

Key sources of Al Straws

Tocal Dairy principally sources straws from three companies. All are based in Australia but two have parent companies overseas. For this reason the proven bulls used may come from Australia, North America (particularly Canada) or Europe.

Distributor of Tocal Milk

In 2019 Tocal moved supply arrangements to Norco Cooperative. Norco offered a significantly higher milk price and a supply bonus for a long-term five-year contract.

Cost of water extraction from Paterson River

Tocal is on the Paterson River an unregulated stream as it is tidal up to the railway bridge at Paterson. It has had its area license converted to a volumetric license of 686 ML with which it historically has irrigated 103 Ha. Its access charge (without meter) is $8.86 per ML per year. This is a recent significant increase. Actual pumping costs can be in excess of $60 per ML for electricity alone. In an effort to reduce energy (electricity) costs, labour requirement and improve application and water use efficiency Tocal has upgraded to centre pivot irrigation on 38 hectares. High pressure Tocal property and farms (2021 update) 60 travelling irrigators which provide many of these advantages were also considered but not preferred due to higher electricity pumping costs.

Describe the technology involved with the following:

Milking;

- Tocal’s system is described as a 15 aside, double up parallel with ACR’s (auto cup removers). Sometimes the technology is hidden (e.g. cup liner design, pulsation control)

- Auto scan infra-red NLIS tags during herd performance evaluation

- Cow cooling includes sprinkler system

- Utilises fully automated CIP (cleaning-in-place)

- Auto-individual drafting

- In 2020 upgrades to the dairy milking shed floor included the installation of specialised rubber matting to improve foot health of cows

Breeding;

- Heat observation (eg. scratchies, marker systems, real time monitoring)

- Oestrus synchronisation and management (hormonal treatments)

- Genetic evaluation (performance recording/herd evaluation, DNA testing, calculation of breeding values)

AI (proven semen, sexed/unsexed, gene marker or “genomic” sires). The current breeding strategy at Tocal dairy is the use of AI for two rounds of sexed semen on the milking herd and one round of sexed semen on maiden heifers. This gives a 95% guarantee of these calves being female and then retained to come into the milking herd.

The bulls used in the breeding program are selected for the traits that they can offer the milking herd – according to their genetic potential. These sires have had their genomic values rated and we are able to select sires that deliver traits that we need Tocal property and farms (2021 update) 61 for our milking herd. Gene markers can include milk production and physical confirmation, fertility, heat tolerance and now feed efficiency is starting to be investigated, amongst others.

Any cows or heifers that do not hold to the two sexed semen matings are then either AI’d or naturally mated to Angus bulls. The Angus bull gives calves traits more suited to beef production and these calves can be sold to beef producers to grow out. This strategy has almost eliminated Holstein bull calves that are sold as young bobby calves.

Herd management

- A new hydraulic crush and yards have upgraded the safety of dairy cow and heifer handling.

- The dairy has benefited from three new silos with upgrades to feed mixing equipment, a new farm track running north south connecting the dairy to Glendarra was constructed and the continuation of the program to have electronic collars on cows, over 280 cows now having collars.

- The use of electronic collars began in 2018, NSW Department of Primary Industries invested in the latest herd management technology, the “HeatTime Pro+ System” SCR by Allflex.

- These collars will track heat detection, movement, calving alerts and rumen health with all information sent back to computer, mobiles and iPad’s via a data receiver located at the dairy.

- The use of these collars allow us to confidently use sexed semen as we can accurately time the mating of cows.

Dairy staff also make use of:

- Calf rearing (colostrum collection, testing and feeding; BJD control and the 3 Point Calf Plan)

- Herd health (biopsy, worm testing, genetic defect testing)

- Biosecurity (NLIS scheme, vendor declarations)

- Identification (NLIS readers, freeze branding, auto drafting)

- Real time recording (Smart phones)

- Recording software (EasyDairy).

- The bleeding of our dairy cattle as part of a Sentinel Herd virus testing program continues under the guidance of our local LLS veterinarians.

Pasture/ supplementary feed

- 2018 saw the installation of three new centre pivot irrigators covering an area of 38 hectares. Centre pivot irrigation is a more efficient system than traditional irrigation allowing output to be varied as needed on different parts of the paddock. This increase in irrigation combined with access to reliable water increases production potential of the farm.

- GPS and auto-steer based technologies in tractors

- Rate and section control for boom-spray application of chemicals

- Currently trialling low bandwidth farm connectivity network and sensor technology including soil moisture probes

- Plant breeding allowing species selection

- Research into best fit rotations (eg. CFR- Complementary Forage Rotations)

- Soil fertility testing and treatment (eg. NDVI- Normalised Difference Vegetation Index)

- Suppression of existing pasture (including herbicide)

- Minimum tillage sowing (eg. direct drilling)

- Irrigation scheduling (e.g. tensiometers)

- Feed assessment (eg. feed analysis, infrared spectroscopy)

- Grazing management (eg. Rotation Right Tool)

- Fodder Conservation (eg. round bale or pit silage)

- Nutrition (eg. feed analysis, ration formulation and checking)

- Feed out (eg. PMR/TMR, feedpads)

- Individual bale feeding

Pastures used on the dairy

Two main pasture systems exist depending on soil type. Podsolic ridge soils have a permanent kikuyu base. White clover persists ephemerally in the kikuyu pasture depending upon season. Most kikuyu paddocks are suppressed in early autumn to allow introduction of winter growing annual pastures, predominately Italian ryegrass but also oats. Other species may be introduced into these mixes including short lived, perennial herbs/forbs such as chicory and plantain. If carefully managed, the kikuyu base returns to dominance over the following summer when the cool season ryegrass or oats deteriorates and before summer weeds can invade. Alluvial flat soils are deeper and have generally better chemical and physical properties. If floods can be avoided they offer the opportunity to fully cultivate the soil with less erosion risk and the introduction of deeper-rooted crops and pastures. They can therefore be used to grow the pasture rotations described for the ridge soils but also pastures such as Lucerne. Corn (maize) has also been grown here in the past but is exposed to flooding risk at establishment and harvest.

Factors that make this a good location for a dairy farm

- Tocal has ample irrigation water at relatively low cost

- High rainfall which is reasonably reliable

- Normally relatively favourable soil moisture autumn and winter

- Temperatures allow reasonable growth from temperate species over winter and particularly spring

- Frosts are relatively infrequent

- Topography includes a mix of flat and ridge country

- Has good access to markets and fertiliser including poultry litter

- Labour is not as difficult to source as some inland dairy regions

Aspects of the biophysical environment that are not ideal for dairy farming at Tocal and how they are managed

Low soil moisture spring and summer (eliminates option of most temperate perennials). Managed with:

- irrigation

- fodder conservation

- fodder purchases

- species selection on the dairy

Frosts and low winter temps (eliminates option of some C4 perennials and reduces the productivity of others including negligible winter growth and poor quality. This creates major winter feed gap). Managed with:

- annual winter crop rotation

- fodder conservation

- species selection on the dairy

Extreme rainfall events (floods and drought). Managed with:

- fodder conservation

- feed pad on the dairy

Acid Kurosol (podsol) subsoils (unsuitable for some pasture species, reduces productivity of others including reduced root growth). Managed with:

- lime

- use of poultry manure

- species selection on the dairy

Low P Kurosol (podsol) soils (reduces productivity of most productive improved species). Managed with:

- fertilising (SSP, DAP)

- use of poultry manure

- species selection on the dairy

Low N soils (reduces productivity of most productive improved species). Managed with:

- fertilising (Poultry litter, Urea)

- inclusion of legumes on the dairy

Shallow, duplex soils on ridge (including podsols) with low RAW (Readily Available Water) values leading to frequent water deficit. Managed with:

- irrigation scheduling (see Using Climate Data for Irrigation Scheduling at https://www.nswdpi-schools-program.com/tocal-virtual-farm

- minimum tillage to reduce erosion and increase organic matter

- species selection- Kikuyu (drought avoiding, self-mulching) on the dairy

High THI (Temperature Humidity Index) reduces grazing time of cows and therefore reduces milk production as well as affecting fertility. Managed with:

- Shade trees

- Sprinklers at dairy

Managing the impacts of climate changes

Autumn is becoming warmer and springs are becoming drier. This is narrowing the window for the cool season pastures oversown into the kikuyu. Managed with:

- species selection

- suppression of kikuyu

- irrigation

Weather extremes are managed with:

- irrigation

- fodder conservation

- grain and other supplement purchasing

- manipulation of stock numbers (destocking)

- forward purchasing of grain

Impacts Tocal has on the environment and the ways we manage each of these issues

Lithosphere- Soils

Compaction is managed with:

- evaluate soil moisture before trafficking

- use minimum tillage

- use of feedpad

- use laneways

- schedule irrigation

Erosion is managed with:

- minimum tillage

- promote good coverage by fertilising and irrigation

- maintain minimum ground cover (70-100% dependent on slope)

- modify grazing pressure

- maintain riparian buffer zone

Loss of fertility is managed with:

- inorganic fertilisers (SSP, Urea, DAP, Blends)

- organic fertilisers (mainly poultry litter) (high P, moderate N, low K plus OM and others)

- use all types responsibly (split rates, observe maximum recommended application rates, soil test and apply as needed, check with nutrient budgets, time with rainfall/irrigation but avoid runoff/ deep drainage)

- encouragement of legume component or legume crop

- irrigation of effluent on to pasture

Acidification is managed with:

- use fertilisers responsibly (see above)

- irrigation scheduling

- effluent containment and recycling

- liming

Hydrosphere

Local waterway pollution (sedimentation, eutrophication etc) is managed with:

- riparian buffer zones

- tree lots and/or undisturbed, thick perennial pasture in gullies Tocal property and farms (2021 update) 66

- minimum tillage and timed paddock preparation with rainfall

- responsible use of fertiliser (see above)

- effluent containment and recycling- major recent investment allows irrigation over approx 70 hectares

Biosphere

Local biodiversity is managed with:

- riparian buffer zones

- tree lots in gullies and laneways

- timber corridors and retention of remnant vegetation

- use of IPM including reduced reliance on insecticides and herbicides

- maintenance of perennial pastures

- retention of some native/naturalised pasture

Atmosphere

Pollutant (methane, farm equipment emissions etc) is managed with:

- methane- feed high quality diet, encourage efficient animal husbandry practices, use of ionophores/rumen modifiers such as monensin

- nitrogen gasses- observe application rate recommendations and time appropriately with conditions (e.g. urea with rainfall, low wind, cultivated soil or thick grass coverage

- nitrate- not saturated soil

- CO2 – avoidance of burning practices, encouragement of OM, conduct of energy audit (use of variable speed pumps, heat recapture, solar being investigated), regularly replace and maintain equipment, use of minimum tillage and adoption of plastic silage wrap recycling

Tocal links with the rest of the world (external links)

Breeding

Tocal Dairy principally sources straws from three companies. All are based in Australia but two have parent companies overseas. For this reason the proven bulls used may come from Australia, North America (particularly Canada) or Europe.

Farm/Pasture technology

A large number of pasture varieties are bred and trialled in NZ or other overseas countries before being bred up here. Most inorganic superphosphate fertiliser is imported. Fossil fuel for fertiliser or direct use is also often imported. High tech equipment such as tractors, balers, spray equipment is often imported. Most pasture chemicals are imported. Milking machine technology and equipment is often designed in North America (Canada or USA) or Europe (UK, Netherlands, France) although increasingly manufacture is in Asian countries. This includes milking consumables.

Information/ideas sharing

Tocal Dairy utilises information from all over the world but principally from regions with similar climate and production system (e.g. coastal, temperate pasture based Tocal property and farms (2021 update) 67 farming). It particularly utilises the information network provided by Dairy Australia and NSW DPI. Programs include In Calf, Countdown Downunder, Cool Cows, Rearing Healthy Calves and numerous pasture trials. Tocal also provides information including trial results and feedback on bull progeny performance. Recently it invited dairy reproduction specialists from Sydney University to analyse its herd data. It has been the venue for many farmer field days and regularly sends members of its team to those held throughout the Valley.

Other external links

Tocal hosts work experience students (vets, high school), trainees, full time students and farmer groups. Tocal has an exchange program with its sister College (Gifu) in Japan. It frequently hosts professional agriculturalists, educators and trainers from around Australia and the world.

Over 20 Sydney University Vet students completing their large animal practical placements at the Tocal Dairy in 2019. These students have come to the dairy during breaks in the Tocal full time student program. This training relationship has been a long one and highly valued by both Sydney University Vet Science department and Tocal.

Tocal links with the rest of Australia (internal links)

Movement of milk/ milk products (to where in Australia?)

Tocal milk normally is processed in Sydney and may be sent from here throughout the state (and occasionally interstate). It currently costs around 10 cents per Litre to transport milk from Victoria to Sydney. For this reason milk producers in NSW normally enjoy a price premium above Victorian producers of around 8 cents per Litre. Should the margin be greater than this then Victorian milk would be encouraged to be supplied into Sydney at the expense of local milk. Manufactured products such as cheeses or yoghurt are normally produced in specialised factories in specific regions or states and then transported nationwide.

Breeding technologies

Australian produced AI straws are mainly from Victoria (the major dairy state) but sires may be sourced from all other states except the NT.

The dairy herd management program, EasyDairy is purchased from a Victorian company who also provide back up.

Herd performance evaluation information is collected on farm (with milk samples tested in a Victorian central lab). This information is analysed by Dairy Express in Armidale before being provided back to Tocal. This information may be combined with genetic information provided by ADHIS (Australian Dairy Herd Improvement Scheme) to make breeding and culling decisions.

ADHIS collects its information from herds all over Australia, from herd performance evaluation services such as Dairy Express and from similar agencies world-wide.

Tocal dairy has contracted to Sydney Uni for pregnancy and breeding services.

Supplementary feed/ medicines

- Grain from Tamworth, Liverpool plains, North West NSW

- Canola meal from the Riverina district of NSW

- Tocal property and farms (2021 update) 68 Calf pellets from Tamworth

- Veterinary products are purchased from vets at Maitland and Muswellbrook

Labour force

Permanent staff live at Paterson, Maitland and Dungog. Temporary staff and contractors are from Maitland, Dungog, Gresford and Clarencetown. Tocal students and work experience students also supply labour. Consultants and advisors from Paterson, Maitland, Sydney, Muswellbrook, Taree and Nowra as well as NSW DPI staff based at Tocal and elsewhere throughout the state.

Information and idea sharing

Tocal is used for research and demonstration by NSW DPI. It is a venue for farmer workshops and discussion/field days. It engages with other agencies such as Dairy Australia, Dairy NSW, local CMA, NCDE (National Centre for Dairy Education in Australia), local LHPA. The Tocal herd is a sentinel herd for the national monitoring of Arboviruses by Animal Health Australia. Tocal dairy frequently participates in agricultural and vocational education industry reviews e.g. continuing review of the duopoly of the two major supermarkets and their effect on milk pricing.

Effects of global changes on Tocal dairy farm

How exposed is Tocal to changes in the global economy?

Tocal dairy is less directly impacted by the global economy now that we supply the Norco Cooperative as a large proportion of their milk products are sold and consumed domestically.

However, the dairy industry in general is significantly impacted by the global economy. Around 36% of Australian dairy production exported therefore influenced by global supply and demand factors. Dairy Australia’s In Focus document published annually provides a good overview of the Australian dairy industry.

https://www.dairyaustralia.com.au/industry/farm-facts/in-focus

The global economy also affects price of imports. Lower $AU may increase these but not normally as much as milk price. Global supply/demand factors more likely to affect price of imported inputs, especially fertiliser, fuel, grain. Even though grain is locally sourced the export price underpins the domestic so supply/demand factors and exchange rate critical to its price on farm.

Changes in global economy can have a dramatic and rapid effect on Australian dairy farmgate milk price with little opportunity for the farmer to adjust production accordingly in the short term. E.g. After a sudden indication of improved milk prices it takes a long time to build up national or individual herd cow numbers (3 years from birth to herd entry plus very little opportunity to increase herd replacement rate anyway). Pastures/feedbase and conserved fodder also takes at least 1-2 years to ‘ramp up’. On the other hand, if the global economy creates price signals for reduced production it is very difficult to ‘turn the milk tap off’. Even with suddenly lowered milk price the current herd must still be milked daily and fed to remain healthy and fertile. There are significant numbers of increased herd replacements still to enter the system and usually the main establishment cost of increased pasture production has been spent. For this reason dairy farmers must often operate at a short term loss when price signals deteriorate rapidly (loss minimisation) and in order to retain the potential to respond to any sudden improvement in price signal.

If production remains unprofitable in the longer term there are actions the farmer can Tocal property and farms (2021 update) 69 take to reduce losses but often maintenance expenditure is curtailed. This makes it very difficult to respond to the next price improvement and can only occur for so long before the farm becomes unviable.

The effect of foreign dairy trade policies on Tocal dairy farm

Australia produces 6% of world dairy (milk equivalents). Many of its competitors on the world market subsidise production or the export of dairy products while many other nations also invoke tariffs to protect their local dairy industries. This means that for Australia to be competitive they must have very low cost of production (similar to NZ and some emerging dairy trading nations in South America). Changes in world dairy trade policies can have a dramatic and rapid effect on Australian dairy farmgate milk price with little opportunity for the farmer to adjust production accordingly in the short term, similar to the effect of sudden global changes above.

The effect of foreign dairy trade into Australia

Australia is the second lowest cost of production exporter and was sufficiently competitive with NZ such that little product from there was imported into Australia.

Import predictions and impacts are discussed in Dairy Australia’s Situation and Outlook https://www.dairyaustralia.com.au/industry/dairy-situation-andoutlook

External global changes that are likely to have the greatest impact on Tocal dairy farm in the future

- Increasing disposable income of the south-east Asian consumer.

- Trade liberalisation

- Competition for resources- fuel, fertiliser, grain Renewable energy policy (global as well as national)- as it affects demand for the above three commodities

- The possibility of the adoption of an Emissions Trading Scheme or similar policy for agriculture

- Biosecurity - ‘clean’ Australian product image must be retained

- Global climate uncertainty - mostly indirectly. Tocal may be at competitive advantage due to projected changes and water supply from Lostock. However competition for resources overall, including water, could have dramatic negative effect

Tocal newsletter

Want to find out about news, events, courses and publications?